VisionTo produce globally competent Mechanical Engineers.

MissionTo develop creative and oriented Mechanical Engineers by

- Educating, preparing and mentoring students to excel as professionals and leaders.

- Imparting add-on technical skills through collaborations & trained faculty and strengthening continuing education.

- Providing knowledge and competence in solving real world problems.

- Promoting participation in technical programs and active involvement with technical associations.

Our Graduates are expected to:

PEO-1: Apply their mechanical engineering education to address the full range of technical and societal problems and excel in profession practice with integrity and responsibility.

PEO-2: Be a professional and promote sustainability, following ethical practices and is committed to the welfare of society.

PEO-3: Possess the intellectual enthusiasm that empowers lifelong learning and enables a versatile response to the challenges of the modern world.

PEO-4: Succeed in their respective careers with expertise in multidisciplinary fields.

PSO-1: Empower the students to apply practical skills in Thermal Engineering, Fluid Engineering, Automotive Engineering and Industrial Engineering using modelling and simulation tools.

PSO-2: Develop the capacity to use comprehensive analytical tools to solve complex engineering problems in the Design, Production, and Manufacturing industries.

PROGRAM OUTCOMES (PO)

Engineering Graduates will be able to:

PO1-Engineering knowledge: Apply the knowledge of mathematics, science, engineering Fundamentals and an engineering specialization to the solution of complex engineering Problems.

PO2-Problem analysis: : Identify, formulate, review research literature, and analyze complex Engineering problems reaching substantiated conclusions using first principles of mathematics, Natural sciences and engineering sciences.

PO3–Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

PO4–Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions

PO5–Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

PO6–The Engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

PO7–Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

PO8–Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

PO9–Individual and team work:. Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

PO10– Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PO11- Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

PO12- Life -long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Computational Fluid Dynamics R&D Projects:

“CFD analysis of merged airfoil for incompressible and compressible flows”, “Comparison of heat transfer between a helical and straight tube heat exchanger”, “CFD analysis of fluid flow and heat transfer in a conical spiral tube heat exchanger” was undertaken in the department and was guided by Prof. Bibin Prasad. All these works has been published in the International Journal of Applied Engineering Research(IJAER)

CFD analysis work guided by Prof.Shan M Assis on “Numerical simulation and Performance investigation of an enhanced Carbondioxide refrigeration system” is the ongoing work in this area. Analysis based on triple tube helical heat exchanger, finned spiral Gas cooler, trapezoidal tube-in-tube heat exchanger will be evaluated.

Composite Material Development:

Research work on “Mechanical property evaluation of Coir reinforced Aluminium laminate epoxy” done by final year B.Tech Mechanical engineering students M Harishankar Nair, Anoop Khan P, Deepak S and Joji Oommen George was partially supported by Central Coir Research Institute of India and the ‘Composite Characterization and Testing division’ of Indian Space Research Organisation. The paper has been published in the International Journal of Applied Engineering Research(IJAER). Students got permission from Defence Research and Development Organisation (DRDO), for further testing of the newly developed composite material. The project was guided by Prof. Shan M Assis

Based on the results of “Projectile Impact Testing” from DRDO, a new work has been initiated in 2014 by Prof Shameer V Hameed by trying a new composition of materials.

PUBLICATIONS

Department always encourages and promotes faculty and students to publish and present their research papers. Details of some of them are:

- “CFD analysis of merged airfoil for incompressible and compressible flows”, International Journal of Applied Engineering Research (IJAER), Vol 8 (2013), No 03, pp 259-271, Bibin Prasad et alc

- “Comparison of heat transfer between a helical and straight tube heat exchanger”, International Journal of Engineering Research and Technology (IJERT), Vol 06, No 01 (2013) , pp 33-40, Bibin Prasad, Sujith V, Mohammed Shaban K, Haneef, Sandeep N, Vishnu Raj

- “CFD analysis of fluid flow and heat transfer in a conical spiral tube heat exchanger”, proceedings of National Conference on Emerging Trends in Mechanical Engineering, Lord Jagannath College of Engineering and Technology, Kanyakumari, 2012, pp 145-148, Suradh K Surendran, Jithin K, Bichu, Sreekanth N

- Mechanical property evaluation of Coir reinforced Aluminium laminate epoxy, International Journal of Applied Engineering Research, ISSN 0973-4562 Volume 9, Number 18 (2014) pp. 4857-4868, Shan M Assis, M Harishankar Nair et al

- “Optimization Of X Cut Wire In Wc Edm Process By Taguchi Method And Comparison By Sem Analysis”, Proceedings of the International Conference on Innovations in Design and Manufacturing, Mar Athanasius College of Engineering, Kerala, India, 10, 11 January 2013, Paper No. M142, Vishnuprasad V N, Anand N

- “An Investigation of Mechanical Properties of Aluminium 6063-T6 after Friction Welding Process”, International Journal of Engineering Trends and Technology (IJETT), V17(5),203-207 Nov 2014. ISSN:2231-5381, Al Faizal .B , Amarnath T S , Roshan T Ninan.

- “Wire EDM machining of stainless steel 316 using cobracut-D wire and comparison with the x-cut wire”, International conference on EMERGING TRENDS IN ENGINEERING AND TECHNOLOGY, Travancore Engineering college, Kollam, Kerala, India, 31 March, 1 April 2014, Rahul Krishnan.

- “Configuration development of inertial propulsion system for satellite maneuvering, International conference on EMERGING TRENDS IN ENGINEERING AND TECHNOLOGY, Travancore Engineering college, Kollam, Kerala, India, 31 March, 1 April 2014, S.Sarath.

- “Investigation on the Influence of Cutting Parameters in Hard Turning”, International conference on EMERGING TRENDS IN ENGINEERING AND TECHNOLOGY, Travancore Engineering college, Kollam, Kerala, India, 31 March, 1 April 2014, Sinu K Jacob.

- ”Material optimization and stress analysis in the cylinder head of a 4 stroke petrol engine”, International conference on EMERGING TRENDS IN ENGINEERING AND TECHNOLOGY, Travancore Engineering college, Kollam, Kerala, India, 31 March, 1 April 2014, Akhil M Nair

Department of Mechanical Engineering is organizing 5 days Add-on Certificate workshop on ‘HVAC drafting & Designing – Fundamentals ’ from 3.03.2023 to 08.03.2023

An initiative of the ‘ISHRAE MCET student Chapter’ in association with ISHARE Trivandrum chapter

- Commencement of B Tech Classes :

S8: 30-01-2023

S6: 06-02-2023

S4: 06-02-2023

Department conducted Faculty Development Programme on Design of Experiments and Recent Developments in Optimization Techniques from 26th June 2019 to 28th June 2019. The sessions were handled by Dr. Anil Lal, (Department of Mechanical Engineering, College of Engineering Trivandrum), Dr. Adarsh S, (Department of Civil Engineering, TKM College of Engineering, Kollam), Dr. K. Sunilkumar, (Department of Mechanical Engineering, College of Engineering, Adoor), Prof. Premchand V P, (Department of Mechanical Engineering, Mar Baselios College of Engineering & Technology, Trivandrum) and Prof. Ajith Kuriakose Mani, (Department of Mechanical Engineering, Saintgits College of Engineering, Kottayam).

The department conducted a webinar on Role of Artificial intelligence in CFD on 16th August 2020. The session was handled by Dr. Reby Roy, Associate Professor, TKM College of Engineering, Kollam. The idea of bringing AI (Artificial Intelligence) to the world of CFD (Computational Fluid Dynamics) was effectively conveyed through the webinar.

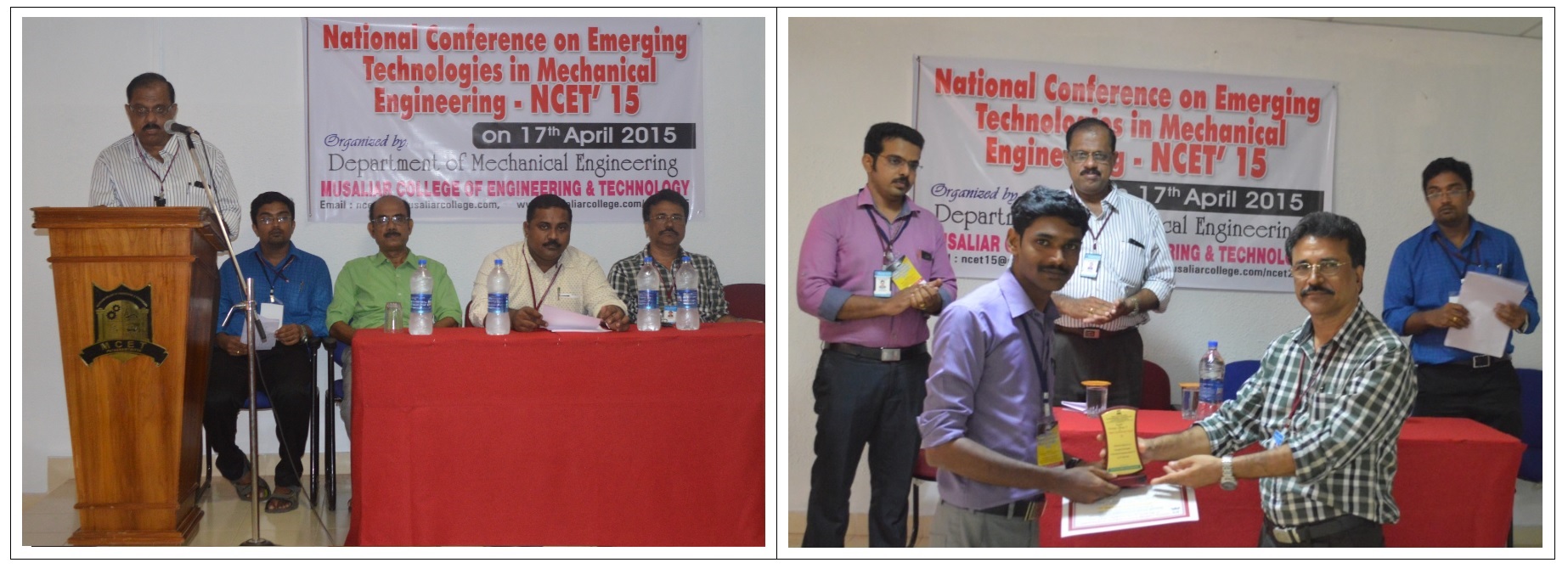

Department conducted National Conference on Emerging Technologies in Mechanical Engineering (NCET-2015) on 17th April 2015. The sessions were chaired by Dr. Mohammed Sajid N K, Professor, TKM College of engineering, Kollam , Dr. K A Shafi, Associate Professor, TKM College of engineering, Kollam, Dr.Bijulal D, Professor, School of Management, College of Engineering, Trivandrum and Dr.Kurian Antony, Assistant Professor, Amal Jyothi College of Engineering, Kanjirappally.